PUZO-1 for ZOM obstruction lights

Low intensity obstruction lights control box PUZO-1

Specifications 27.12.31-003-28320930-2018

Introduction:

This operation manual is intended for preliminary

study by service staff, its use during installation, as well as, its whole

subsequent operation period. The staff are allowed to operate this equipment,

who have the appropriate qualification, have studied operation principles and

this manual.

Objective:

The obstruction lights control box is intended

for automatic switching on/off of the light obstruction complex of a high

object depending on outdoor daylight conditions, as well as, for the

obstruction lights forcible switching on (independent of a light-sensitive

relay command). It is installed directly on high objects. PUZO-1 was

specifically designed to control the obstruction lights: ZOM and SDZO

Specifications 27.40.39-004-28320930-2018 independent of a light

source, and is intended for the operation in harsh climatic conditions. The obstruction

lights control box is manufactured in the special electric ABS-plastic box with

high electric and mechanical operation specifications.

Technical specifications:

· ABS-plastic body;

· Dimensions (A*B*C), mm – 201*128*120;

· Weight: no more 2kg;

· Protection class: IP65, GOST 14254-96 (All-Union State Standard);

· Rated power voltage: single-phase 220V, 50Hz;

· Output power voltage: single-phase 220V, 50Hz;

· Incoming circuit number: 1;

· Outgoing circuit number: 1;

· Lights electronic switching system in the twilight with 5-10000lux brightness range with outdoor light

sensor in IP65 climatic embodiment.

Operation conditions:

The obstruction lights control box PUZO-1 is intended

for the outdoor installation and operation directly on high constructions at ambient

temperature from -50 to +50 ºС, relative humidity up to 80% at 25ºС, at the height no more

that 2000m above sea level, without aggressive atmospheric mixtures causing

corrosion.

The climatic PUZO-1embodiment according to GOST 15150-69—UHL

2.1 (All-Union State Standard). The operation with mechanical environmental

impact factors according to M1 GOST 17516.1-90 (All-Union State Standard).

Safety measures:

The personnel is allowed to mount and operate the

obstruction lights control box PUZO-1, who completed training courses, have a

permit in accordance with “Regulations for Operation of Consumer Electrical

Installations” and

“Safety Rules for Operation of Customers' Electrical

Installations” and whose

safety qualification group is not lower III.

The measures to protect the service personnel

against electric current shock:

By its protection method against electric

current shock PUZO-1 complies with a.7.4.2.1, a.7.4.2.2 GOST 22789-94 (All-Union State

Standard).

By its protection method against indirect

touch of current-conducting parts the device complies with the requirements of a.7.4.3.1 GOST 22789-94 (All-Union

State Standard) (insulation cross-section of the copper conductor must be no

less than 4 mm2).

Operation preparation and installation

order:

Before the device installation it is required

to define the exact location for cables laying, as well as, the location for

the obstruction lights installation according to the design documentation.

The procedure of cable laying and obstruction

lights installation must be carried out in the following climatic conditions:

· Humidity: no more 80%;

· Ambient temperature: no lower 5ºС.

The obstruction lights are mounted on a base stand with outer G ¾”

thread.

The obstruction light base is screwed on a base stand then fixed by a

locking crew. The radius of cable lines bend must not be less than 5 cable

diameters.

The cable lines connection to the LED obstruction lights is made

according to the electric circuit diagram. The connection order of power and

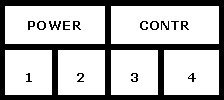

control cables to the LED module is shown in figure 1.

The outputs 1 and 2 of the terminal unit,

shown on the module board “Power”, are intended to connect power cables. The

polarity is not mandatory.

The outputs 3 and 4 of the terminal unit,

shown on the module board “Contr”, are intended to connect the monitoring

status control cable, which is unavailable in this equipment configuration.

The connection for the obstruction light with

an incandescent lamp is made in accordance with a holder type.

The obstruction light is connected with a 2*1,5mm2

cable. Two conductors of a cable are connected to 1 and 2 contacts of the

terminal unit (power). From the back side, a cable is connected to the terminal

units of the switch box (hereinafter, BOX). Afterwards, BOX is connected with a

2*2,5 mm2 cable (recommended armoured cable) to 3 and 4 terminal contacts (Line 1) on PUZO-1 dashboard.

The photo sensor is connected to 1 and 2

contacts with a 2*0,75mm2 cable.

Next, the obstruction lights station is mounted

on its location. Afterwards, all outer cables are connected to the terminal

unit of the appropriate input PUZO-1 contacts, located left of the automatic

unit.

Device and its performance:

The obstruction lights control box PUZO-1

consists of:

· Automatic system power switch (2A);

· Electronic lights switching system with 5-10000 lux brightness range and outdoor light sensor;

· Automatic switch for force obstruction lights and protection short-circuit systems switching-on (2A).

Performance:

220V power voltage is connected to N and L

terminal unit located to the left of the automatic unit. The outdoor light

sensor sends a command to switch on the obstruction lights power, if daylight

brightness changes. The relay sensitivity is controlled in 5-10000lux range,

besides, 30-second relay operation delay is designed to prevent accidental

short switching-off.

The switch “Power” is available on the

obstruction lights front dashboard, which switches on or off incoming device

power voltage, as well as, the switch “Line-1”, which can be used for forced

obstruction lights switching-on (independent of a light-sensitive relay

command).

Maintenance:

The visual inspection and checkup of all cable

connections reliability, as well as, contacts revision must be made no less

than once a month. If it is required, the electric circuit fixtures must be

tightened.

Storage and transportation:

PUZO-1 storage warranty is no more than 24 months

since its manufacture date.

The obstruction lights

control box PUZO-1 must be stored in the factory packaging, in an unheated

warehouse at 0 -+40 ºС ambient temperature and 98% relative humidity at +35º С. The warehouses must not have any

aggressive mixtures causing corrosion.

The obstruction lights control station PUZO-1transportation

must be done in the factory packaging by railway or automobile transport

(covered wagons, trucks, containers) at -50 - +50º ambient temperature and 98%

humidity (upper level) at +25º in accordance with load transportation

regulation which is currently effective for each type of transport.

Manufacturer

warranty:

The company guarantees 2-year

non-failure device operation, if all operation, transportation and storage

rules are observed since its operation.

Data about claims:

The claims are made to the supplier in case any

defects and malfunctions can be found, which lead to the device breakdown

before the warranty period expires.

You should state in the claim report: the factory

device number, defects and malfunctions, conditions under which they were

found, the operation time of the device. The copy of the payment document for

the device must be attached to the report.